How are Sips panels joined together?

Another of the 20 most regular questions our team receive is “How are Sips panels joined together?”

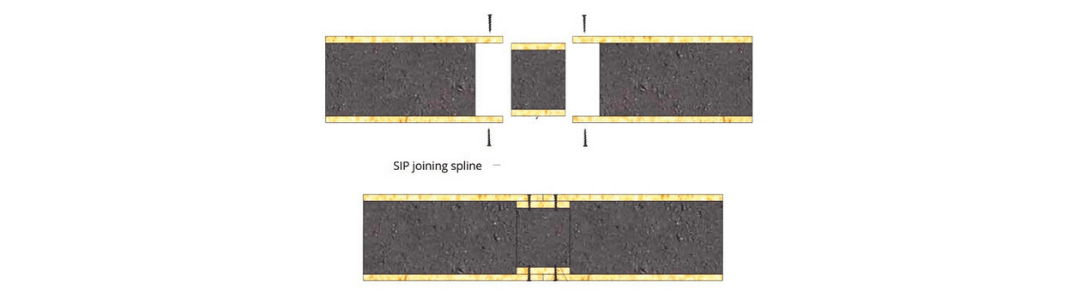

SIPs panels are joined together with an insulated SIP spline. This is a full-length spline that joins both panels together. The spline like the panels are also insulated with EPS (expanded polystyrene) and has an outer OSB (oriented strand board) skin to strengthen the joint. This also helps to eliminate cold bridging.

Cold bridging is where there are spaces in the continuous insulation where hot air can escape from the building and cold air can leak in. By using our insulated spline, it solidifies the joints and makes them airtight meaning the structure will be exceptionally strong whilst also being thermally resistant. This is a great benefit.

Traditional timber frame houses can lose in excess of 30% of household energy whereas our panels paired with our insulated splines will drastically reduce the amount of energy escaping. This is great for helping reduce energy bills!

Joining Sip Panel to Sip Panel

As you can see from the diagram above, the Sip panels are joined together with an insulated spline fitted inside. Screws are then screwed through the OSB of the panel and into the spline OSB to make the joint very strong and secure, glue may be used at this point as well to seal the joint and give it extra strength.

Joining Sip Panel to Ground Foundations

After the foundations of a house has been laid, there is a 45 mm timber sole (bottom plate) laid down on the foundations as demonstrated in the diagram above.

After the foundations of a house has been laid, there is a 45 mm timber sole (bottom plate) laid down on the foundations as demonstrated in the diagram above.

The SIP panels have a gap of 45mm between the EXP and the bottom of the OSB. This means that the 45mm timber sole/bottom plate laid fits snug into the bottom of the boards.

The boards are then screwed to the plates to fix them in place and ensure the structure is strong and sturdy.

Let us know if you have any questions, we are a helpful team at Sips Eco Panels!

Contact Us